About Us | Blog | FAQs | Tips/Troubleshoot | Contact Us | Machine Manuals | Demo Videos

2025 Top Commercial Vacuum Packing Machine Buying Guide and Reviews

In the rapidly evolving food packaging industry, the significance of a reliable commercial vacuum packing machine cannot be overstated. As John Smith, a leading expert in food preservation technology, aptly puts it, "Investing in a high-quality commercial vacuum packing machine can significantly extend the shelf life of perishable products, ensuring both quality and safety." With increasing consumer demand for fresh and long-lasting food products, businesses are turning to advanced vacuum packing solutions that meet their specific needs.

In this comprehensive buying guide, we will delve into the critical aspects you need to consider when selecting the best commercial vacuum packing machine for your operations. From understanding the different types of machines available to evaluating essential features such as sealing strength, chamber size, and ease of use, we will provide you with the insights required to make an informed decision. Furthermore, we will highlight key reviews and comparisons from industry professionals to help you navigate the options available in the market.

Whether you are a small business owner or part of a large-scale operation, the right commercial vacuum packing machine can transform your packaging process, enhance food preservation, and ultimately drive consumer satisfaction. Join us as we explore the various facets of these essential machines, ensuring that you make the best choice for your commercial needs.

Table of Contents

[Hide]

Key Features to Consider When Choosing a Vacuum Packing Machine

When selecting a commercial vacuum packing machine, several key features should be carefully considered to ensure you choose the right equipment for your needs. One of the primary aspects to evaluate is the sealing capability. Look for machines with powerful and reliable sealing systems that can handle various packaging materials, from vacuum bags to rolls. The quality of the seal is crucial for preserving food freshness and preventing leaks, which can compromise product integrity.

Another important feature to consider is the machine's capacity and size. Depending on your production requirements, you may need a model that can handle larger volumes or one that fits within limited workspace. Additionally, features such as adjustable vacuum levels and programmable settings can enhance flexibility, allowing you to tailor the packing process for different types of food items or products. Ease of use and maintenance should also factor into your decision, as a user-friendly design will minimize training time and operational delays, while a machine that is easy to clean and maintain will promote longevity and reliability.

Types of Commercial Vacuum Packing Machines Available in 2025

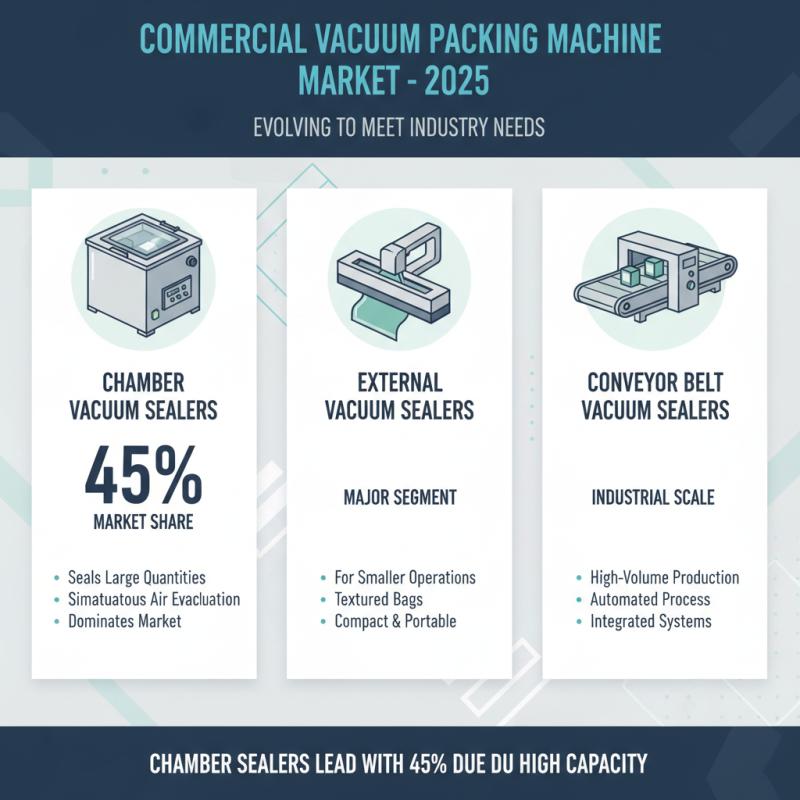

In 2025, the commercial vacuum packing machine market continues to evolve, offering a diverse range of machines designed to meet the needs of various industries. The primary types of vacuum packing machines available fall into three categories: chamber vacuum sealers, external vacuum sealers, and conveyor belt vacuum sealers. According to recent industry reports, the chamber vacuum sealers dominate the market, accounting for nearly 45% of the total share due to their ability to seal large quantities of products simultaneously while evacuating air from a sealed chamber.

External vacuum sealers, on the other hand, are favored for their portability and ease of use, making them ideal for small businesses and catering services. These machines are designed for quickly sealing smaller batches, with a reported efficiency improvement of about 30% over traditional sealing methods. Meanwhile, conveyor belt vacuum sealers provide high throughput for industrial applications, often used in food packaging plants where speed and efficiency are paramount. Data indicates that the demand for conveyor belts has increased by approximately 20% as businesses seek to automate their packaging processes to keep up with market demands.

As sustainability becomes a priority, manufacturers are also investing in eco-friendly materials and energy-efficient technologies, which are predicted to drive growth in this sector further. The global market for commercial vacuum packing machines is expected to grow at a CAGR of 5.6% between 2025 and 2030, highlighting the importance of choosing the right type of machine to enhance operational efficiency and sustainability in packaging practices.

Top Brands of Vacuum Packing Machines and Their Unique Offerings

When considering the purchase of a commercial vacuum packing machine, it's essential to explore the top brands and their unique offerings. Each manufacturer has developed its own niche in the market, catering to various business needs. Some brands excel in producing machines that prioritize speed and efficiency, allowing businesses to process large volumes of packaging quickly. These machines often feature advanced technology that enhances seal strength and ensures product longevity, making them ideal for high-demand environments such as restaurants and food processing plants.

Other brands focus on versatility, providing vacuum packing machines that can handle a range of products, from delicate items like herbs to bulkier goods like meats and cheeses. These machines typically come with multiple settings and attachments, allowing users to customize their operations based on specific requirements. Additionally, there are brands that emphasize user-friendly designs, ensuring that operators can easily learn how to use the machinery, ultimately maximizing productivity and minimizing training time. By understanding these unique offerings, businesses can make informed decisions that align with their operational goals.

User Reviews: What Buyers Are Saying About 2025 Models

When looking for the best commercial vacuum packing machines in 2025, user reviews play an essential role in guiding potential buyers. Customers often highlight their satisfaction with machines that offer both reliability and efficiency. Many users emphasize the importance of investing in a model that not only seals products tightly but also does so quickly, helping to enhance workflow in busy commercial settings. The feedback reflects a growing preference for machines that are user-friendly, with intuitive controls and easy maintenance, as this can significantly reduce operational downtime.

Tips for prospective buyers include considering the size and capacity of the vacuum packer to ensure it meets the volume of products that need to be packed. Additionally, look for features such as adjustable sealing times and vacuum levels, which can tailor the machine's performance to various types of food or products. Some reviews also suggest seeking machines with durable construction, as this can lead to long-term cost savings through reduced repairs and replacements.

Moreover, functionality and versatility are often significant points in user discussions. Machines that come with multiple modes for different packaging needs tend to receive higher praise. Buyers should examine the warranty and customer support offered, as these factors can greatly influence the long-term satisfaction with the purchase. Overall, user reviews serve as a valuable resource for understanding the real-world performance and reliability of commercial vacuum packing machines in 2025.

Maintenance Tips for Prolonging the Life of Your Vacuum Packing Machine

Maintaining your vacuum packing machine is essential for ensuring its longevity and optimal performance. Regular upkeep not only helps in avoiding costly repairs but also ensures that your machine functions efficiently, preserving the freshness of your foods. Here are some crucial maintenance tips to keep your vacuum packing machine in top shape.

First and foremost, clean the sealing area after every use. Food particles and residues can accumulate, affecting the sealing process and potentially leading to malfunctions. Use a soft damp cloth to wipe down the sealing strip and the surrounding surfaces, making sure to remove any barbs or debris. Additionally, inspect the sealing strip for signs of wear or damage, and replace it if necessary, as a worn strip can result in poor seals.

Another important tip is to check and clean the vacuum pump regularly. Over time, oil or moisture can build up, which may hinder the machine's performance. Refer to the manufacturer’s recommendations for your specific model regarding how to clean the pump and replace any filters. Lastly, store your vacuum packing machine in a cool, dry place away from direct sunlight and extreme temperatures. Proper storage not only protects the machine from environmental damage but also helps maintain its components for a longer lifespan.

Commercial Vacuum Packing Machine Maintenance Tips

Related Posts

-

7 Essential Tips for Choosing the Right Commercial Vacuum Packing Machine

-

How to Choose the Best Double Chamber Vacuum Sealer for Your Business Needs

-

Navigating Export and Import Certifications for the Best Commercial Vacuum Packing Machines in Global Markets

-

How to Choose the Right Commercial Vacuum Packing Machine for Your Business

-

The Ultimate Guide to Maximizing Freshness with an Industrial Vacuum Sealer

-

7 Essential Certifications for Importing the Best Vacuum Food Sealer Machines Worldwide