About Us | Blog | FAQs | Tips/Troubleshoot | Contact Us | Machine Manuals | Demo Videos

Innovative Examples of Best Table Top Tray Sealing Machines for Global Buyers

In the ever-evolving landscape of food packaging, the demand for efficient and reliable equipment has led to innovations in machinery design, particularly in the realm of table top tray sealing machines. According to a recent report by Markets and Markets, the global packaging machinery market is expected to reach USD 50.38 billion by 2025, growing at a CAGR of 4.4%. This growth underlines the importance of investing in high-quality sealing machines that cater to the needs of various industries, including food service, pharmaceuticals, and consumer goods.

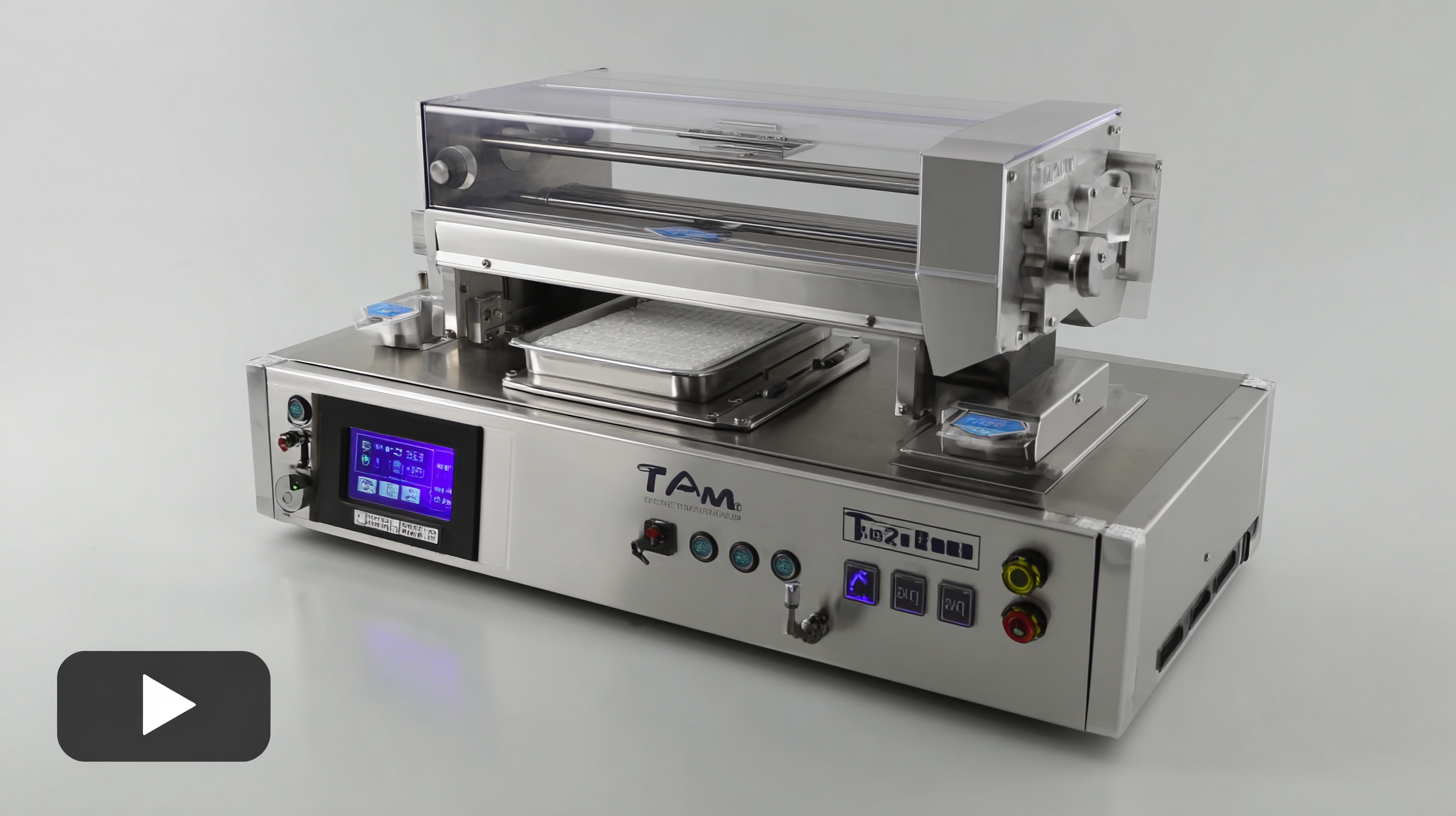

Table top tray sealing machines are at the forefront of this trend, offering versatility and ease of use for small to medium-scale operations. As buyers worldwide seek efficient solutions to enhance their packaging processes, understanding the features and benefits of these machines becomes crucial. This ultimate guide explores innovative examples of the best table top tray sealing machines available today, equipping global buyers with the knowledge to make informed purchasing decisions.

Table of Contents

[Hide]

Innovative Technologies in Table Top Tray Sealing Machines: An Overview of Key Features

The evolution of table top tray sealing machines has significantly transformed the packaging landscape, offering innovative technologies that enhance efficiency and product integrity. Modern machines incorporate advanced features such as automatic sealing, adjustable temperature control, and programmable settings, which cater to a variety of materials including plastic and aluminum. According to a recent industry report from the Packaging Machinery Manufacturers Institute (PMMI), the market for automated packaging machinery is projected to grow at a CAGR of 4.5% through 2026, underscoring the increasing demand for efficient packaging solutions in food and consumer goods.

When considering the purchase of a table top tray sealing machine, buyers should look for models that offer superior functionality and user-friendly interfaces. Machines equipped with vacuum sealing capabilities can extend the shelf life of perishable items by up to 50%, reducing food waste and enhancing product quality. Furthermore, features like quick-change tooling can improve production flexibility, enabling businesses to adapt to varying order sizes without extensive downtime.

Tip: Always assess the energy efficiency ratings of the machine you are considering. Energy-efficient models not only lower operational costs but also appeal to environmentally conscious consumers. Additionally, ensure that any machine you choose complies with local health and safety regulations to protect both your product and your workforce.

Comparative Analysis of Top Table Top Tray Sealing Machines: Performance Metrics and Efficiency

When exploring the world of table top tray sealing machines, it's essential to focus on performance metrics and efficiency to make the best choice for your operations. Top models in the market differ significantly in terms of sealing speed, power consumption, and ease of use. For instance, some machines can achieve sealing speeds of up to 20 trays per minute, which is crucial for high-demand environments. Additionally, energy-efficient models not only reduce operational costs but also enhance sustainability efforts, which is increasingly important to buyers worldwide.

Tips: Always consider the material compatibility of your sealing machine, as using the correct materials ensures optimal performance and minimizes waste. Furthermore, pay attention to user reviews and machine warranties; reliable feedback can offer insights into real-world performance that specifications alone may not reveal.

The efficiency of these machines also relates to their maintenance requirements. A well-maintained sealing machine can consistently perform at peak efficiency, reducing downtime and increasing productivity. Regular cleaning and scheduled maintenance checks are vital. Plus, investing in machines with easy access for routine checks can save time and enhance operational flow in busy settings.

Understanding Technical Specifications: What Makes a Tray Sealing Machine Stand Out?

When considering tray sealing machines, understanding their technical specifications is crucial for discerning what sets one model apart from another. Key specifications such as sealing temperature, pressure, and speed play significant roles in the efficiency and quality of the sealing process. For instance, a machine that offers adjustable sealing temperatures can accommodate various materials, ensuring optimal adhesion and preventing damage to sensitive products. Additionally, machines that provide consistent sealing pressure will enhance product integrity, reducing the instances of leaks and spoilage.

Another factor that distinguishes innovative tray sealing machines is their automation capabilities. Advanced models are designed with user-friendly interfaces and programmable settings, allowing operators to achieve consistent results with minimal manual intervention. Features such as real-time monitoring and data logging enable manufacturers to track performance and adjust processing parameters promptly, boosting production efficiency. Furthermore, machines that incorporate hygienic designs and easy-to-clean components ensure compliance with food safety standards, making them a preferred choice for businesses in the food and beverage sector. These technical specifications reflect not only the machine's functionality but also its adaptability to diverse industry needs, making them valuable investments for global buyers.

Step-by-Step Tutorial: How to Operate and Maintain Table Top Tray Sealing Machines for Longevity

Operating and maintaining table top tray sealing machines requires a systematic approach to ensure their longevity and efficiency. First, it is essential to familiarize yourself with the machine's specifications and features. Begin by reading the manufacturer’s manual carefully to understand the components and their functions. When setting up the machine, ensure that all connections are secure and that the heating elements are replaced if worn out. This initial setup is crucial for achieving the best sealing results.

Next, regular maintenance routines can significantly enhance the lifespan of your machine. Cleaning the sealing area after each use helps prevent buildup that could lead to malfunctions. Additionally, inspect the sealing molds and heating elements periodically for any signs of wear or damage. It is advisable to perform a thorough inspection weekly or bi-weekly, depending on the volume of use. Lubricating moving parts as specified in the manual can also prevent excessive wear and promote smooth operation. By following these steps diligently, you can maximize the performance of your table top tray sealing machine and ensure it remains in top condition for years to come.

Industry Trends: The Future of Tray Sealing Technology and Its Global Market Impact

The global tray sealing machines market is on a promising trajectory, showcasing a significant estimated growth from USD 1.29 billion in 2024 to an impactful expansion by 2030, with a CAGR of 4.3%. This growth is largely fueled by the rising demand for efficient packaging solutions across various industries, particularly in the food sector. As companies strive to enhance product longevity and preserve quality, the evolution of tray sealing technology becomes paramount. Innovations in smart tray sealing systems are likely to play a pivotal role in meeting consumer demands for convenience and sustainability.

Tips for choosing a tray sealing machine include evaluating production speed, which is crucial for high-volume operations. Additionally, consider machine versatility, as adaptable systems can handle various tray sizes and materials, thereby accommodating a range of products. Finally, look for manufacturers that offer robust support and maintenance services, ensuring your equipment remains efficient and operational over time.

Understanding these industry trends not only helps global buyers make informed decisions but also positions them to leverage new technologies for competitive advantage in the market. This proactive approach is essential as the packaging landscape continues to evolve in response to changing consumer preferences and stricter industry regulations.