About Us | Blog | FAQs | Tips/Troubleshoot | Contact Us | Machine Manuals | Demo Videos

Common Challenges Facing Commercial Vacuum Packers

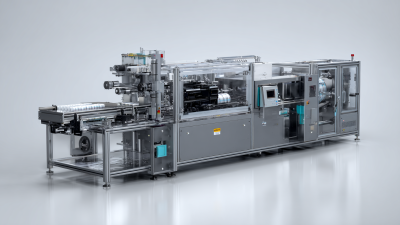

In the rapidly evolving landscape of food packaging, commercial vacuum packers have emerged as essential tools for enhancing product shelf life and maintaining quality. However, as businesses strive to keep pace with consumer demands and technological advancements, they face a myriad of challenges that can impede their operational efficiency. From the intricacies of machine maintenance to the complexities of optimizing vacuum settings for different products, understanding and addressing these obstacles is crucial for ensuring the longevity and effectiveness of commercial vacuum packers.

In the rapidly evolving landscape of food packaging, commercial vacuum packers have emerged as essential tools for enhancing product shelf life and maintaining quality. However, as businesses strive to keep pace with consumer demands and technological advancements, they face a myriad of challenges that can impede their operational efficiency. From the intricacies of machine maintenance to the complexities of optimizing vacuum settings for different products, understanding and addressing these obstacles is crucial for ensuring the longevity and effectiveness of commercial vacuum packers.

This blog will delve into the common challenges that operators encounter, exploring how these issues not only impact productivity but also influence the future of packaging solutions in the industry. By examining these hurdles, we aim to provide insights that will help businesses adapt and thrive in a competitive market.

Table of Contents

[Hide]

Key Factors Impacting the Efficiency of Commercial Vacuum Packers in Food Production

In the realm of food production, commercial vacuum packers play a crucial role in preserving freshness and extending shelf life. However, several key factors can significantly impact their efficiency. One of the most critical elements is the quality of the vacuum sealer itself. Manufacturers must ensure that the equipment has a strong, reliable seal to prevent air from entering the package, which can lead to spoilage. Additionally, regular maintenance and inspection are essential to avoid equipment malfunctions that can interrupt the packing process and result in material waste.

Another important factor is the skill and training of operators. Even the most advanced vacuum packers can underperform if not used correctly. Staff should be well-trained in operating the machines and adhering to best practices for food safety. This includes understanding the specific requirements for different food types, as varying moisture levels and shapes can affect sealing performance. Furthermore, the layout of the production area can influence efficiency; optimizing workflow to reduce bottlenecks ensures a smoother operation and faster packing times, ultimately enhancing productivity and minimizing downtime.

Understanding the Importance of Vacuum Seal Quality: Ensuring Freshness and Shelf Life

Vacuum packing is an essential process in the food industry, significantly impacting food freshness and shelf life. According to a report by the Food and Agriculture Organization (FAO), proper vacuum sealing can extend the shelf life of food products by 2 to 5 times compared to traditional storage methods. This is primarily due to the reduction of oxygen, which slows down the growth of aerobic microorganisms and enzymes that lead to spoilage. For manufacturers, maintaining a high-quality vacuum seal is crucial not only for the preservation of taste and texture but also for meeting regulatory standards regarding food safety.

Vacuum packing is an essential process in the food industry, significantly impacting food freshness and shelf life. According to a report by the Food and Agriculture Organization (FAO), proper vacuum sealing can extend the shelf life of food products by 2 to 5 times compared to traditional storage methods. This is primarily due to the reduction of oxygen, which slows down the growth of aerobic microorganisms and enzymes that lead to spoilage. For manufacturers, maintaining a high-quality vacuum seal is crucial not only for the preservation of taste and texture but also for meeting regulatory standards regarding food safety.

Furthermore, industry data indicates that up to 30% of food products can be lost due to inadequate packaging solutions. A research study conducted by the Institute of Food Technologists (IFT) highlighted that consumers often associate poor seal quality with inferior product quality, which can affect brand reputation and sales. Ensuring a robust vacuum seal is thus pivotal for commercial vacuum packers, as it directly correlates with consumer satisfaction and retention. Investing in advanced sealing technology can mitigate these challenges, leading to enhanced product integrity and lower food waste in the supply chain.

Analyzing the Cost Implications of Common Vacuum Packing Challenges for Businesses

Commercial vacuum packers play a crucial role in preserving food quality, extending shelf life, and minimizing waste. However, businesses often face several challenges when implementing these systems, which can have significant cost implications. One primary concern is the initial investment required for high-quality vacuum packing machinery. While these machines are designed to enhance efficiency, the upfront costs can strain small and medium-sized enterprises, particularly if they are not prepared for potential maintenance and operational expenses.

Additionally, businesses must consider the costs associated with training staff to effectively operate vacuum packing machines. Inadequate training can lead to improper usage, resulting in inefficiencies and even product spoilage, ultimately affecting profit margins. Furthermore, businesses may encounter challenges related to packaging materials, as subpar or incompatible materials can increase the likelihood of product compromise, necessitating additional expenditures on replacements or loss of inventory. By addressing these challenges strategically, companies can optimize their vacuum packing processes and better manage associated costs, ensuring a more sustainable approach to food preservation.

The Role of Maintenance and Upkeep in Reducing Downtime for Vacuum Packing Equipment

Commercial vacuum packers are essential tools in many food production and packaging operations, but keeping these machines running efficiently requires diligent maintenance. Regular upkeep not only extends the life of the equipment but also drastically reduces unexpected downtime, which can be costly. Failure to perform routine checks on seals, motors, and vacuum pumps can lead to significant operational hiccups. Simple tasks, like cleaning and calibrating the devices, contribute to optimal performance and ensure the machinery remains in peak condition.

Moreover, implementing a proactive maintenance schedule can help identify potential issues before they escalate into major repairs. Training staff to recognize signs of wear or malfunction can also play a crucial role in sustaining vacuum packer performance. By fostering an environment that prioritizes maintenance and encouraging operators to report concerns immediately, businesses can mitigate the risks associated with downtime. In the commercial world, where time is money, the effective management of vacuum packing equipment through regular upkeep ensures seamless operations and enhances overall productivity.

Exploring Technological Advancements in Vacuum Packing to Overcome Industry Challenges

Advancements in vacuum packing technology are crucial for addressing the common challenges faced by commercial vacuum packers. The industry has seen a significant evolution in machinery, with modern vacuum packers now utilizing smart sensors and automated systems to enhance efficiency. According to a report by MarketsandMarkets, the global vacuum packaging market is projected to reach $38.2 billion by 2025, driven by the demand for longer shelf life and reduced food waste. These innovations not only improve operational effectiveness but also help meet stringent food safety regulations.

To maximize the benefits of these technological advancements, commercial packers should consider investing in user-friendly interfaces that streamline operations. For example, choosing machines equipped with programmable settings allows for quick adjustments based on varying product types, which can lead to more consistent results and less downtime.

Tips: When selecting vacuum packing equipment, prioritize features like energy efficiency and durability, as these will reduce operational costs in the long term. Regular maintenance and updates of software can also prevent potential issues, ensuring that your packing process remains smooth and compliant with industry standards. Staying informed about the latest developments in packaging technology can give businesses a competitive edge in a rapidly evolving market.

Related Posts

-

Ultimate Guide to Choosing the Best Industrial Vacuum Sealer Machine for Your Business

-

Future Trends in Best Professional Vacuum Sealer Industry by 2025 and How to Maximize Your Investment

-

7 Essential Tips for Choosing the Best Vacuum Sealer for Your Kitchen Needs

-

Innovative Examples of Best Table Top Tray Sealing Machines for Global Buyers

-

Ultimate Comparison of the Top Vacuum Food Sealer Machines for Home Use

-

7 Key Advantages of Utilizing the Best Seal Packing Machine for Your Production Line