About Us | Blog | FAQs | Tips/Troubleshoot | Contact Us | Machine Manuals | Demo Videos

How to Choose the Right Commercial Vacuum Packing Machine for Your Business

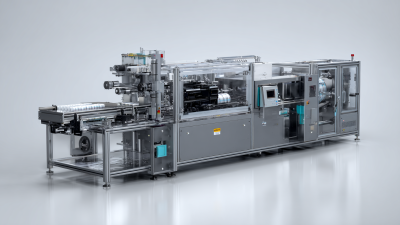

Choosing the right commercial vacuum packing machine is a critical decision that can significantly impact the efficiency and profitability of your business. With a myriad of options available in the market, selecting a machine that meets your specific requirements can seem overwhelming. Factors such as the volume of products to be packed, the type of materials used, and the desired shelf life of your goods must all be considered.

This guide aims to provide you with essential insights into the key features and specifications of commercial vacuum packing machines, enabling you to make an informed choice that aligns with your operational needs. Whether you are in the food industry, pharmaceuticals, or any other sector that requires effective packaging solutions, understanding the nuances of these machines will help streamline your processes and ensure you maximize the benefits they offer.

Table of Contents

[Hide]

Understanding Different Types of Commercial Vacuum Packing Machines and Their Applications

When selecting a commercial vacuum packing machine for your business, it's essential to understand the different types available and their specific applications. There are primarily three categories of vacuum packing machines:

chamber vacuum sealers, external vacuum sealers, and conveyor belt vacuum sealers.

Chamber vacuum sealers are ideal for high-volume operations, as they can seal multiple bags simultaneously, effectively accommodating large products.

According to a 2021 market research report by Grand View Research, the global vacuum packaging market is expected to reach $48.6 billion by 2028,

highlighting the growing demand for efficient packaging solutions across various industries.

External vacuum sealers, on the other hand, are more suited for smaller businesses or those with less frequent sealing needs.

They work best for sealing dry products and are often more affordable and portable.

Meanwhile, conveyor belt vacuum sealers cater to continuous production processes, making them indispensable in food processing plants and industrial settings.

Understanding these differences can significantly affect your operational efficiency and cost-effectiveness.

A survey from Packaging Strategies indicated that 68% of food producers consider packaging efficiency a key driver in their purchasing decisions,

underscoring the importance of selecting the right equipment for your specific business needs.

Key Features to Consider When Selecting a Commercial Vacuum Packing Machine

When selecting a commercial vacuum packing machine, there are several key features to consider to ensure it meets the specific needs of your business. First and foremost, the size and capacity of the machine are crucial. You need to assess the volume of products you plan to package regularly. Machines vary in chamber sizes and bag compatibility, so it’s important to choose one that can handle your largest items while optimizing for space efficiency.

Another essential feature to look for is the sealing technology. High-quality vacuum sealing ensures that your products remain fresh and protected from contamination. Choose a machine with adjustable sealing settings, which will allow you to accommodate different types of bags and products. Additionally, consider the durability and maintenance requirements of the machine. A robust construction will not only extend the life of the equipment but also reduce downtime and maintenance costs, ensuring your operations run smoothly.

Evaluating the Cost-Effectiveness of Vacuum Packing Machines in Your Business

When evaluating the cost-effectiveness of vacuum packing machines for your business, it is crucial to consider both initial investment and long-term savings. High-quality machines may come with a heftier price tag, but they often offer superior efficiency and durability, allowing businesses to pack products more quickly and with greater reliability. Lower-priced machines may save money upfront, but they can lead to increased maintenance costs and downtime, ultimately affecting productivity and profitability.

Additionally, consider the impact of vacuum packing on the shelf life and quality of your products. By investing in a vacuum packing machine, businesses can significantly reduce spoilage and waste, translating into higher overall savings. Furthermore, vacuum-sealed packaging can enhance the presentation of products, leading to increased sales. Ultimately, a thorough analysis of both the financial and operational benefits will ensure that your investment in a vacuum packing machine aligns with your business goals and yields optimal returns.

Cost-Effectiveness of Different Vacuum Packing Machines

Comparing Industry Standards: Durability and Reliability of Leading Vacuum Packing Brands

When selecting a commercial vacuum packing machine, assessing the durability and reliability of leading brands is crucial for ensuring long-term performance and efficiency. Industry reports indicate that high-quality vacuum packing machines can last for over 10 years, significantly surpassing the lifespan of lower-end models that may fail within just a few years. For instance, a study by Packaging World highlights that brands like Vacmaster and FoodSaver are renowned for their robust construction and reliable seals, which prevent air from re-entering vacuum bags, thus maximizing food preservation.

Additionally, a survey conducted by the National Restaurant Association reveals that nearly 75% of food businesses prioritize durability and reliability when choosing vacuum packing equipment. This trend emphasizes the need for investing in machines that can withstand daily use without compromising functionality. Leading brands often integrate advanced technologies, such as double seal systems and stainless steel construction, to enhance their machines' endurance. By focusing on these aspects, businesses can ensure they choose vacuum packing machines that not only meet industry standards but also facilitate streamlined operations and reduce long-term costs.

Analyzing the Impact of Vacuum Packing on Food Shelf Life and Quality Preservation

Vacuum packing has emerged as a crucial method for prolonging the shelf life of food products while maintaining their quality. By removing air from packaging, vacuum sealing reduces the growth of bacteria and mold, which are accelerated by exposure to oxygen. This technique not only preserves the freshness and flavor of food items but also minimizes food waste, making it an effective solution for businesses aiming to enhance their food storage practices.

When selecting a commercial vacuum packing machine, it is vital to consider the specific needs of your business. Ensure the machine is capable of handling the volume and type of food products you offer. Some tips for choosing the right machine include evaluating the sealing technology, determining the required vacuum strength, and assessing the ease of use and maintenance. Additionally, consider machines that allow for adjustable sealing times and temperatures, as different foods require varying levels of care during the packing process.

Optimal vacuum packing can significantly extend the shelf life of perishable items such as meats, cheeses, and vegetables while maintaining their original texture and taste. Leveraging this technology can enhance customer satisfaction and loyalty, as consumers appreciate the quality and freshness of their food. Investing in the right vacuum packing machine will not only benefit your products but also reinforce your brand's commitment to quality and sustainability.

Related Posts

-

7 Key Advantages of Utilizing the Best Seal Packing Machine for Your Production Line

-

7 Reasons Why the Table Top Tray Sealing Machine is Essential for Your Business

-

Navigating Export and Import Certifications for the Best Commercial Vacuum Packing Machines in Global Markets

-

How to Identify Superior Suppliers for the Best Commercial Vacuum Packing Machines

-

7 Essential Certifications for Importing the Best Vacuum Food Sealer Machines Worldwide

-

Future Trends in Best Professional Vacuum Sealer Industry by 2025 and How to Maximize Your Investment