About Us | Blog | FAQs | Tips/Troubleshoot | Contact Us | Machine Manuals | Demo Videos

Navigating Import Export Certifications for the Best Cryovac Machine Choices Worldwide

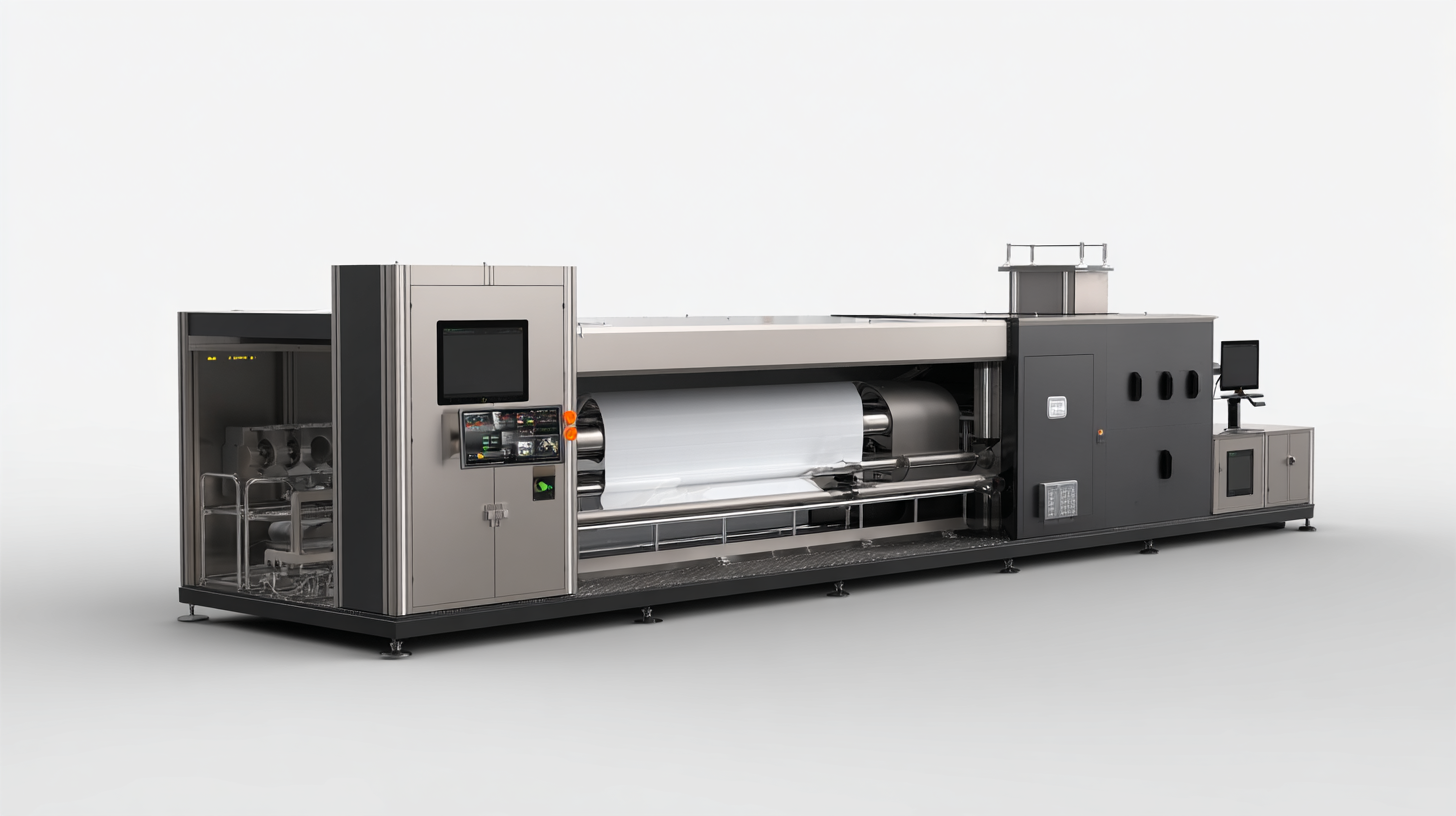

In today's globalized market, the demand for efficient packaging solutions has spurred a significant interest in cryovac machines, which play a critical role in food preservation and shelf-life extension. According to industry reports by MarketsandMarkets, the global food packaging market is projected to reach USD 500 billion by 2025, showcasing a compound annual growth rate (CAGR) of 5.1%. As manufacturers and import-export professionals navigate the intricate landscape of certifications required for these machines, understanding the distinct characteristics and application scopes of various cryovac models becomes essential. With an array of options available in the market, it is crucial to select the right type of cryovac machine that not only complies with international standards but also meets specific product requirements, thereby enhancing operational efficiency and ensuring product integrity across borders.

Table of Contents

[Hide]

Understanding the Importance of Import Export Certifications for Cryovac Machines

Import export certifications play a crucial role in the global trade of Cryovac machines. These certifications serve as a guarantee that the machines meet international standards for safety, efficiency, and environmental impact. Countries often have specific regulations that must be adhered to, making these certifications essential for manufacturers and suppliers looking to penetrate various markets. Understanding and navigating the certification process can significantly influence a company's ability to operate internationally, as well as bolster its reputation among consumers who prioritize quality and compliance.

Moreover, for buyers, these certifications provide peace of mind. They ensure that the Cryovac machines they are purchasing have undergone rigorous testing and meet required safety and operational benchmarks. This is particularly important in industries where reliability and hygiene are paramount. Furthermore, possessing up-to-date certifications can enhance a company’s competitiveness in the market, opening doors for partnerships and new business opportunities across borders. As such, understanding the importance of import export certifications is vital for anyone looking to make informed decisions in acquiring Cryovac machines globally.

Key Certification Standards for Cryovac Machinery in Global Markets

When considering Cryovac machines for import and export, it's essential to understand the key certification standards that influence their acceptance in global markets. Certifications such as ISO 9001, which ensures quality management systems, play a crucial role in establishing the reliability of machinery used in food packaging and preservation. Compliance with such standards not only facilitates smoother trade processes but also reassures buyers of the product’s performance and safety.

Additionally, certifications like CE marking, which signifies compliance with health, safety, and environmental protection standards in Europe, can greatly enhance a Cryovac machine's marketability. In regions with strict regulations, such as North America and the EU, having the appropriate certifications can mean the difference between successful market entry and costly setbacks. By focusing on these certification standards, businesses can navigate the complexities of international trade and position themselves competitively in the Cryovac machinery landscape.

Emerging Technologies Shaping the Future of Cryovac Machines by 2025

As the demand for efficient food packaging solutions continues to grow, the future of Cryovac machines is poised to be transformed by emerging technologies. By 2025, innovations in materials science and automation are expected to significantly alter how these machines function, enhancing not only functionality but also sustainability. Advanced polymers and bio-based materials are being researched to create packaging solutions that reduce environmental impact while maintaining the high barrier properties that Cryovac machines are known for.

Furthermore, the integration of smart technology will revolutionize the operational capabilities of Cryovac machines. With the rise of IoT (Internet of Things) applications, future machines will likely feature real-time monitoring capabilities, allowing operators to optimize production processes and maintain quality control efficiently. These advancements promise to streamline workflows, minimize waste, and ensure that products are better preserved throughout their supply chain, catering to the ever-increasing global standards for food safety and quality. As these trends unfold, companies investing in Cryovac technology will be better positioned to meet the evolving demands of consumers and retailers alike.

Navigating Trade Regulations: A Guide for Importing Cryovac Equipment

When considering the importation of Cryovac equipment, it is crucial to navigate the complex landscape of trade regulations which can significantly impact your purchasing decisions. According to a report by the International Trade Centre, the global market for packaging machinery, which includes Cryovac machines, is expected to grow by approximately 4.5% annually until 2025. However, understanding the import/export certifications required for compliance can be a daunting task for many businesses.

Different countries impose varying regulations that govern the import of packaging technology. For instance, the European Union requires compliance with CE marking, which serves as a guarantee that products meet high safety and environmental standards. Additionally, businesses should be aware of documentation such as the Certificate of Origin and the Importer Security Filing, particularly when dealing with U.S. customs. Failure to provide the necessary certifications not only delays shipment but can also lead to significant penalties. By staying informed about these regulations, companies can make strategic decisions that optimize their supply chains and ensure they procure the best Cryovac machines available worldwide.

Best Practices for Selecting the Right Cryovac Machine for Your Needs

When selecting the right Cryovac machine for your needs, it’s essential to consider several key factors that impact performance and efficiency. According to a recent industry report by Grand View Research, the global food packaging market is expected to reach USD 500 billion by 2025, indicating a growing demand for advanced packaging technologies. The right Cryovac machine can enhance shelf life and reduce food waste, which is crucial in today’s sustainability-focused market.

**Tip:** Always assess your production volume and product types before making a purchase. This evaluation will help you determine the specifications required, such as chamber size and sealing technology. A machine designed for high-volume operations may not be necessary for smaller businesses, potentially leading to inefficiencies.

Moreover, consider the certification and compliance status of the machines you’re evaluating. The right certifications ensure the machine meets safety and quality standards, which is vital for export markets. According to the International Packaging Association, over 70% of companies consider compliance as a significant factor in their equipment choices.

**Tip:** Look for machines that are adaptable to changing regulations, ensuring longevity and relevance in your operations. A flexible Cryovac machine can accommodate various packaging materials and configurations, making it a worthwhile investment as market demands shift.

Navigating Import Export Certifications for the Best Cryovac Machine Choices Worldwide

| Certification Type | Region | Required Documents | Processing Time | Validity Period |

|---|---|---|---|---|

| ISO 9001 | Global | Quality Manual, Audit Reports | 3-6 months | 3 years |

| CE Marking | European Union | Technical File, Testing Reports | 1-3 months | Indefinite (as long as compliant) |

| FDA Approval | United States | Clinical Data, Manufacturing Information | 6-12 months | Indefinite (as long as compliant) |

| UL Certification | North America | Test Results, Product Samples | 3-6 months | 1 year |

| RoHS Compliance | European Union | Material Declarations, Test Reports | 2-4 weeks | Indefinite (as long as compliant) |