About Us | Blog | FAQs | Tips/Troubleshoot | Contact Us | Machine Manuals | Demo Videos

The Ultimate Guide to Maximizing Freshness with an Industrial Vacuum Sealer

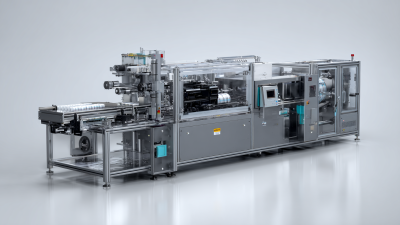

In the realm of food preservation and packaging, an industrial vacuum sealer stands out as an indispensable tool for businesses seeking to maximize freshness and extend the shelf life of their products. As the demand for high-quality, long-lasting food options continues to grow, understanding the capabilities and features of an industrial vacuum sealer becomes essential. This guide will delve into the various types of vacuum sealers available on the market, exploring their functionalities and best practices for effective utilization. By harnessing the power of vacuum sealing, industries can significantly reduce waste, maintain nutritional value, and ensure that their products remain appealing to consumers. Whether you are involved in food processing, storage, or distribution, mastering the art of using an industrial vacuum sealer can elevate your operations and enhance the overall quality of your offerings.

Table of Contents

[Hide]

Understanding Industrial Vacuum Sealers and Their Types

Industrial vacuum sealers play a crucial role in preserving the freshness of products across various sectors, from food processing to pharmaceuticals. Understanding the different types of industrial vacuum sealers is essential for businesses looking to optimize their packaging processes. The primary types include chamber vacuum sealers, belt vacuum sealers, and handheld vacuum sealers, each serving distinct needs.

Chamber vacuum sealers are widely used for their efficiency in sealing larger quantities of product at once. They operate by placing the entire package inside a chamber, removing the air, and sealing it—ideal for businesses with high-volume needs. Belt vacuum sealers, on the other hand, are designed for continuous motion and are suited for assembly lines, offering speed and productivity for high-throughput environments. Lastly, handheld vacuum sealers provide versatility for smaller operations or on-the-go sealing, making it easier to manage tasks without investing in bulky machinery. By comprehensively understanding these types, businesses can select the right industrial vacuum sealer to maintain product integrity and extend shelf life effectively.

Key Features to Look for in an Industrial Vacuum Sealer

When selecting an industrial vacuum sealer, several key features are vital to ensuring optimal performance and maximum freshness preservation. Firstly, it's essential to consider the pump capacity, which significantly influences the sealing efficiency. According to a report from the European Vacuum Packaging Association, machines with a pump rate of at least 20 cubic meters per hour can maintain a pressure difference of up to 99.9%, effectively preventing oxidation and spoilage. This feature not only extends shelf life but also preserves the aroma and flavor of perishable goods.

Next, look for adjustable sealing settings. Different products require specific heat levels for sealing, and machines that offer customizable temperature controls can meet these diverse needs. A study by the Food Processing Suppliers Association reveals that high-quality seals can reduce moisture transfer by up to 70%, which is crucial for products like meats and cheeses. Additionally, robust construction materials, such as stainless steel, ensure durability in busy industrial environments, providing a long-term solution for businesses aiming to enhance their packaging processes and reduce waste.

The Ultimate Guide to Maximizing Freshness with an Industrial Vacuum Sealer - Key Features to Look for in an Industrial Vacuum Sealer

| Feature | Importance | Typical Range | Ideal for |

|---|---|---|---|

| Vacuum Strength | Determines the quality of sealing | 20 inHg - 30 inHg | Meat, vegetables, and perishable items |

| Seal Bar Length | Affects the size of items you can seal | 12 inches - 40 inches | Larger packages and bulk items |

| Pumping Speed | Affects productivity in a commercial setting | 5 - 15 cubic feet per minute | High-volume settings |

| Material Compatibility | Ensures versatility for different packaging materials | Plastic, foil, paper | Food, electronics, hazardous materials |

| User Interface | Simplifies the operation | Digital/Analog Display | Operators with varying skill levels |

Benefits of Using an Industrial Vacuum Sealer for Freshness

Using an industrial vacuum sealer can significantly enhance the freshness of food products, addressing one of the most common challenges in food preservation. According to a report by the Food and Drug Administration, improper storage accounts for about 30% of food spoilage, leading to both economic losses and increased food waste. Industrial vacuum sealers eliminate air exposure, which is crucial, as oxygen is a primary factor in oxidation and microbial growth. By removing air, these sealers can extend the shelf life of perishable goods by 2 to 5 times compared to conventional storage methods.

Moreover, a study published in the Journal of Food Science indicates that vacuum sealing can preserve the nutritional value of food. The sealing process minimizes nutrient degradation, particularly in vitamins and antioxidants, which are sensitive to oxygen. In commercial settings, where maintaining product quality is essential, utilizing vacuum sealing can result in a substantial reduction in spoilage rates and ultimately improve profitability. Businesses that invest in industrial vacuum sealers not only achieve better fresh food preservation but also enhance operational efficiency, creating a win-win scenario for both suppliers and consumers.

Best Practices for Maximizing Freshness When Vacuum Sealing

When using an industrial vacuum sealer, the key to maximizing freshness lies in adopting best practices that ensure optimal sealing and storage. First, always start with high-quality ingredients—fresh produce, meats, and dry goods yield the best results when vacuum sealed. Properly prepare your items by washing and thoroughly drying fruits and vegetables, and cutting them into appropriate sizes to fit in the vacuum bags. Additionally, ensure that food items are cooled to the correct temperature before sealing, as warm food can create steam, compromising the vacuum seal.

Furthermore, utilize the right vacuum bags designed for industrial use. These bags are often thicker and more puncture-resistant, providing better protection against air and moisture. Ensure that the sealer is set to the appropriate vacuum level for the type of food being sealed; delicate foods may require a gentler suction, while tougher items can handle a stronger vacuum. To further enhance freshness, consider incorporating oxygen absorbers or moisture absorbers into the bags before sealing, as they help inhibit spoilage and extend shelf life. By following these best practices, you can effectively maximize the freshness of your food products using an industrial vacuum sealer.

Common Mistakes to Avoid When Using Industrial Vacuum Sealers

When it comes to maximizing freshness with industrial vacuum sealers, avoiding common mistakes can significantly enhance the longevity of sealed products. One prevalent mistake is not ensuring a proper seal. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), a proper seal can increase the shelf life of vacuum-sealed food by up to 50%. For optimal sealing, it's crucial to check for contaminants such as moisture or air that may hinder the sealing process.

Another frequent error is overfilling the bags. Overfilling can prevent the vacuum sealer from achieving a complete seal, leading to air pockets that compromise freshness. A study conducted by the Food and Drug Administration (FDA) suggests that under vacuum conditions, the quality of stored food remains preserved for a fraction of time compared to those improperly sealed. Thus, ensuring that bags are filled appropriately allows for a more efficient sealing process and better preservation results. By paying attention to these details, businesses can maximize efficiency and maintain high product quality in their operations.

The Impact of Common Mistakes on Food Freshness with Industrial Vacuum Sealers

Related Posts

-

Ultimate Guide to Choosing the Best Industrial Vacuum Sealer Machine for Your Business

-

How to Choose the Best Food Vacuum Sealer for Your Kitchen Needs

-

7 Reasons Why the Best Industrial Vacuum Sealer Machine Elevates Your Packaging Efficiency

-

7 Key Advantages of Utilizing the Best Seal Packing Machine for Your Production Line

-

Unlocking the Secrets: Technical Specifications and How to Choose the Best Chamber Sealer for Your Business

-

Common Challenges Facing Commercial Vacuum Packers