About Us | Blog | FAQs | Tips/Troubleshoot | Contact Us | Machine Manuals | Demo Videos

Top 10 Commercial Vacuum Packing Machines to Transform Your Business in 2025

In 2025, the demand for efficient food preservation methods continues to accelerate, pushing businesses to seek innovative solutions like the commercial vacuum packing machine. According to a recent report by the Global Packaging Industry Association, the commercial vacuum packing machine market is projected to grow by over 15% annually, driven by rising consumer expectations for food freshness and safety. As the food service and retail sectors evolve, these machines are not merely tools; they are transformative assets that can significantly enhance operational efficiency and reduce waste.

Industry expert Dr. Emily Thompson, a leading researcher in food packaging technology, emphasizes the impact of advanced vacuum packing systems. She states, “Investing in a commercial vacuum packing machine is not just about preservation; it’s about embracing a future where quality and customer satisfaction go hand in hand.” Her insights underline the critical role these machines play in streamlining operations for restaurants, manufacturers, and distributors alike, enabling them to deliver high-quality products while minimizing spoilage.

With the integration of automation and precision technology, the next generation of commercial vacuum packing machines promises to set new standards in the industry, making it crucial for businesses to stay ahead of the curve. This article explores the top 10 commercial vacuum packing machines that can revolutionize your operations, providing invaluable insights for businesses looking to thrive in this competitive landscape.

Table of Contents

[Hide]

Top Reasons to Invest in High-Quality Commercial Vacuum Packing Machines in 2025

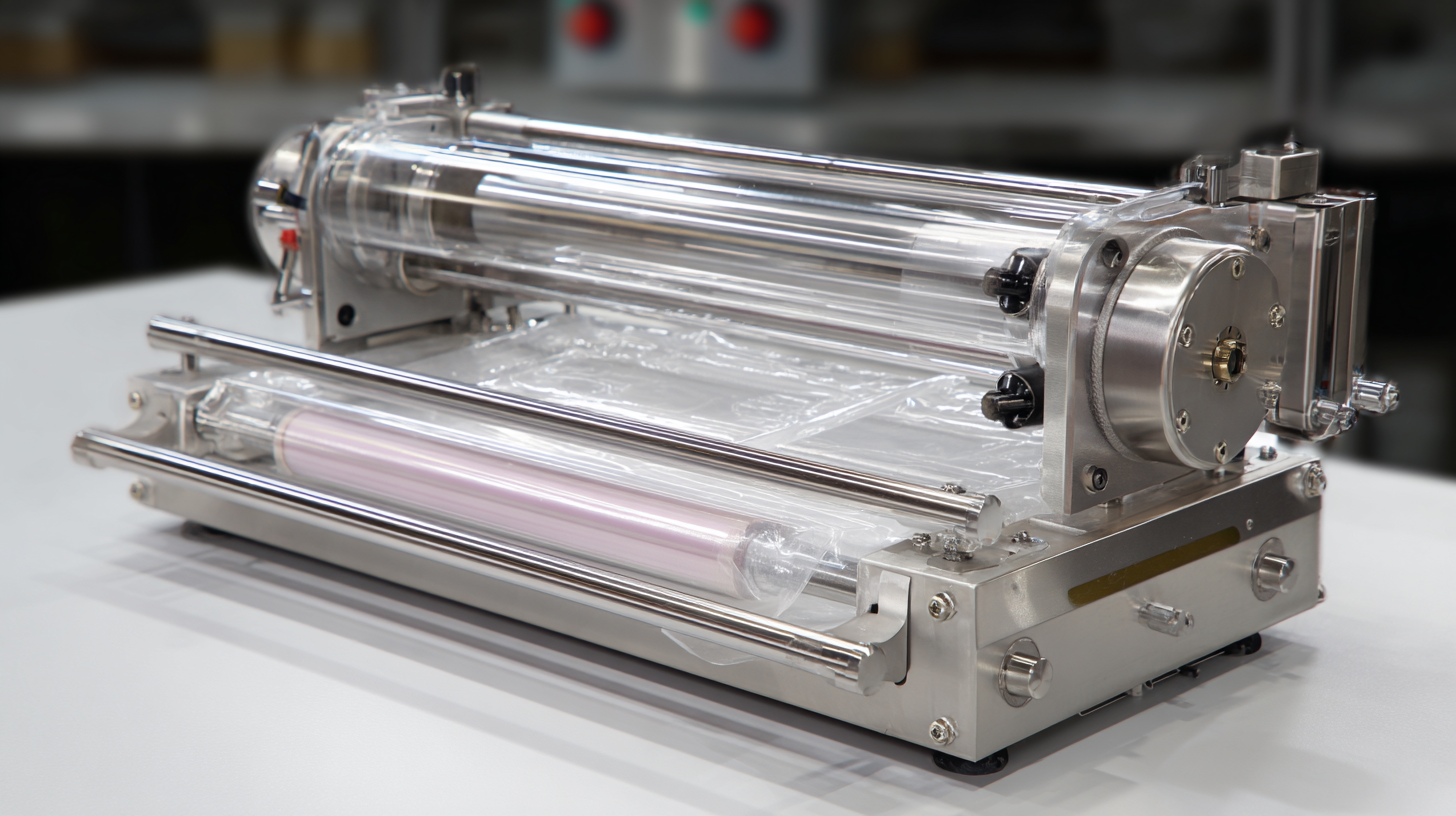

Investing in high-quality commercial vacuum packing machines in 2025 presents a strategic opportunity for businesses looking to enhance their operational efficiency and product longevity. These machines play a crucial role in preserving food quality by removing air, thus minimizing spoilage and extending shelf life. With the increasing demand for packaged goods and the rise in competition, upgrading to advanced vacuum packing technology can significantly improve product presentation and reduce waste.

Moreover, advancements in automation and precision technology make modern vacuum packing machines more user-friendly and efficient. These machines not only streamline the packaging process but also ensure consistency and reliability in production. As seen in recent developments across various industries, including food processing, the integration of automated systems has led to increased productivity and better quality control. By investing in state-of-the-art vacuum packing machines, businesses can position themselves at the forefront of their industries, ready to meet consumer demands and optimize their supply chains for the years to come.

Top 10 Commercial Vacuum Packing Machines to Transform Your Business in 2025

Investing in high-quality commercial vacuum packing machines in 2025 can significantly enhance your business's efficiency. The chart above illustrates the efficiency performance of the top 10 commercial vacuum packing machines, showcasing the advantages of choosing reliable equipment for better productivity.

The Impact of Vacuum Packaging on Food Preservation and Shelf Life Extension

Vacuum packaging plays a crucial role in food preservation, significantly extending the shelf life of various products. By removing air from the package, vacuum sealing minimizes the growth of bacteria, molds, and yeasts, which are the primary culprits of food spoilage. This technology is particularly beneficial for perishable items such as meats, cheeses, and pre-prepared meals, allowing them to maintain their freshness for weeks or even months longer than traditionally packaged goods.

Vacuum packaging plays a crucial role in food preservation, significantly extending the shelf life of various products. By removing air from the package, vacuum sealing minimizes the growth of bacteria, molds, and yeasts, which are the primary culprits of food spoilage. This technology is particularly beneficial for perishable items such as meats, cheeses, and pre-prepared meals, allowing them to maintain their freshness for weeks or even months longer than traditionally packaged goods.

In addition to safety and longevity, vacuum packaging also enhances food integrity. It prevents freezer burn and dehydration in frozen goods, ensuring that the texture and flavor remain intact. As consumers increasingly seek quality and convenience, businesses that adopt vacuum packing systems can meet rising demand while reducing waste. The expansion of the vacuum packaging market reflects this trend, highlighting the necessity of sophisticated packaging solutions for modern food preservation. As we move into 2025, investing in advanced vacuum packing machines will not only streamline operational efficiency but also contribute to a more sustainable food supply chain.

Key Features to Look for in Commercial Vacuum Packing Machines for Optimal Performance

When choosing a commercial vacuum packing machine, several key features can significantly enhance operational efficiency and product quality. According to a recent report by Technavio, the global vacuum packaging market is expected to grow at a CAGR of 5.3% from 2021 to 2025, highlighting the increasing demand for efficient packaging solutions across various sectors, including food and non-food industries. One critical feature is the sealing quality; a robust machine should provide a secure and airtight seal to prolong shelf life and ensure product safety. Machines equipped with advanced sealing technology, like pulse sealing, can handle a variety of packaging materials, ensuring versatility and effectiveness.

Another essential aspect is pump capacity. A high-performing vacuum pump not only expels air quickly but also maintains consistent vacuum levels, which is vital for preserving delicate items or perishables. According to industry standards, a vacuum level below 100 millibar is typically necessary for optimal food preservation. Machines that offer adjustable vacuum levels allow businesses to customize the process depending on the specific product being packed, resulting in better outcomes. Moreover, durability and build quality are crucial; machines made from stainless steel tend to have higher longevity in busy commercial settings, ensuring a good return on investment over time.

Industry Statistics: The Growth of Vacuum Packaging Market and Future Trends

The vacuum packaging market is poised for significant growth, driven by increasing demand across various sectors. By 2024, the global meat packaging market is expected to reach a value of $51.95 billion, with projections indicating a rise to $55.04 billion by 2025 and further climbing to $85.49 billion by 2032. This surge reflects a broader trend in vacuum packaging technologies, which are increasingly utilized to enhance food preservation and reduce spoilage, catering to consumer preferences for longer shelf-life products.

In parallel, the overall vacuum sealing machine market is anticipated to grow from $4.71 billion in 2023 to approximately $7.2 billion by 2032. This growth trajectory aligns with advancements in technology that streamline packaging processes while improving efficiency. With such promising statistics, businesses looking to capitalize on the vacuum packaging trend in 2025 are strategically positioned to transform their operations and meet the evolving demands of consumers and industries alike.

Top 10 Commercial Vacuum Packing Machines to Transform Your Business in 2025

| Machine Model | Chamber Size (L) | Vacuum Speed (m³/h) | Power (kW) | Weight (kg) | Estimated Price (USD) |

|---|---|---|---|---|---|

| Model A | 40 | 5 | 2.0 | 150 | 3500 |

| Model B | 60 | 6 | 2.5 | 180 | 4500 |

| Model C | 80 | 7 | 3.0 | 200 | 6000 |

| Model D | 100 | 8 | 4.0 | 220 | 7500 |

| Model E | 120 | 9 | 4.5 | 250 | 9000 |

| Model F | 150 | 10 | 5.0 | 300 | 11000 |

| Model G | 200 | 11 | 6.0 | 350 | 13000 |

| Model H | 250 | 12 | 7.0 | 400 | 15000 |

| Model I | 300 | 13 | 8.0 | 450 | 17000 |

| Model J | 350 | 14 | 9.0 | 500 | 20000 |

How Advanced Vacuum Packing Machines Can Enhance Operational Efficiency and Reduce Waste

In the fast-evolving food processing sector, advanced vacuum packing machines are pivotal in enhancing operational efficiency and minimizing waste. As their technology continues to advance, businesses can leverage these machines to optimize packaging processes, leading to longer shelf lives and reduced spoilage. By efficiently removing air from packages, vacuum packers not only preserve food quality but also streamline production workflows, allowing for faster turnaround times.

Tips: Consider investing in machines that offer customizable settings to accommodate various packaging needs. This versatility can help cater to different product types while maximizing efficiency.

Moreover, adopting vacuum packing technology contributes to significant waste reduction. With precise sealing processes, less product is discarded due to spoilage or contamination. As businesses seek to adopt more sustainable practices, integrating these machines into production lines becomes an increasingly viable strategy.

Tips: Regularly maintain and calibrate your vacuum packing equipment to ensure consistent performance and longevity. Proper maintenance can prevent costly downtime and enhance overall productivity.

Related Posts

-

Navigating Export and Import Certifications for the Best Commercial Vacuum Packing Machines in Global Markets

-

Common Challenges Facing Commercial Vacuum Packers

-

Ultimate Checklist for Choosing the Right Bag Sealer Machine for Your Needs

-

Ultimate Guide to Choosing the Best Food Packaging Sealing Machine for Your Business

-

5 Essential Tips for Maximizing the Efficiency of Your Cryovac Machine

-

Ultimate Comparison of the Top Vacuum Food Sealer Machines for Home Use