About Us | Blog | FAQs | Tips/Troubleshoot | Contact Us | Machine Manuals | Demo Videos

5 Top Reasons Why the Best Bag Sealer Machine is Essential for Global Procurement

In today's increasingly globalized marketplace, efficient procurement processes are more critical than ever, and the role of the bag sealer machine has become paramount. According to a report by MarketsandMarkets, the global packaging machinery market is projected to reach USD 47 billion by 2024, driven by the growing demand for reliable and cost-effective packaging solutions. A high-quality bag sealer machine not only enhances product integrity but also boosts operational efficiency by reducing spoilage and waste, which is particularly crucial for food and pharmaceuticals. As companies aim to streamline their supply chains, investing in advanced sealing technologies can yield significant competitive advantages, ensuring products remain fresh and compliant with international standards. Embracing these innovations will prepare businesses for the challenges of global procurement and enable them to meet evolving market demands effectively.

Table of Contents

[Hide]

Importance of Bag Sealer Machines in Global Supply Chains

In the realm of global supply chains, efficiency and quality control are paramount, and bag sealer machines play a crucial role in achieving these objectives. According to a recent report by MarketsandMarkets, the global packaging machinery market is projected to reach $53.2 billion by 2024, with bag sealing technologies being a significant contributor to this growth. These machines ensure that products are securely sealed, preventing contamination and spoilage, which is particularly vital as businesses expand into international markets where shipping times can be prolonged.

The importance of bag sealer machines extends beyond mere preservation; they also enhance operational efficiency. A study from the Food and Agriculture Organization (FAO) highlights that effective packaging can reduce food waste by up to 30%. In the context of global procurement, this translates to significant cost savings and a more sustainable supply chain. As companies navigate the complexities of cross-border logistics, investing in reliable bag sealing technologies becomes essential to ensure that products not only reach their destination intact but also meet the high standards expected by consumers worldwide.

Exploring Alternatives to Traditional Bag Sealing Methods

In recent years, the packaging industry has undergone significant transformations as businesses seek alternatives to traditional methods. The wine industry, in particular, has adapted to changing consumer preferences and innovations, with a growing focus on effective sealing solutions. Many are exploring alternatives that not only enhance product preservation but also align with sustainability goals.

One promising development is the production of antimicrobial biodegradable packaging films from nanocellulose derived from corn husk. This innovative approach not only protects food from environmental pollutants but also minimizes environmental impact. As procurement teams look for ways to innovate, investing in modern bag sealer machines can offer a multitude of benefits, such as enhanced efficiency and improved product shelf-life.

Tips:

- When considering alternatives, evaluate the material properties of packaging options for maximum protection and sustainability.

- Stay updated on industry trends and technologies to remain competitive in your procurement strategy.

- Test various sealing methods to find the one that best meets your product requirements while ensuring food safety and longevity.

Cost-Effectiveness: How Bag Sealers Save Money in Procurement

In today's competitive global market, ensuring cost-effectiveness in procurement processes is paramount for businesses seeking to maximize their profits. Among the various tools that facilitate this goal, the bag sealer machine stands out as an invaluable asset. These machines not only improve operational efficiency but also significantly reduce packaging costs. By sealing products securely, they minimize the risk of damage or contamination during storage and transit, ultimately saving companies from incurring extra expenses related to product loss.

Moreover, bag sealers contribute to labor cost reductions. With advanced automation features, these machines streamline the sealing process, requiring less manual intervention. This efficiency allows teams to focus on higher-value tasks, thus optimizing labor resources. Overall, investing in a high-quality bag sealer machine helps organizations cut down on initial procurement costs while providing long-term savings and increased productivity, reinforcing the importance of this equipment in successful global procurement strategies.

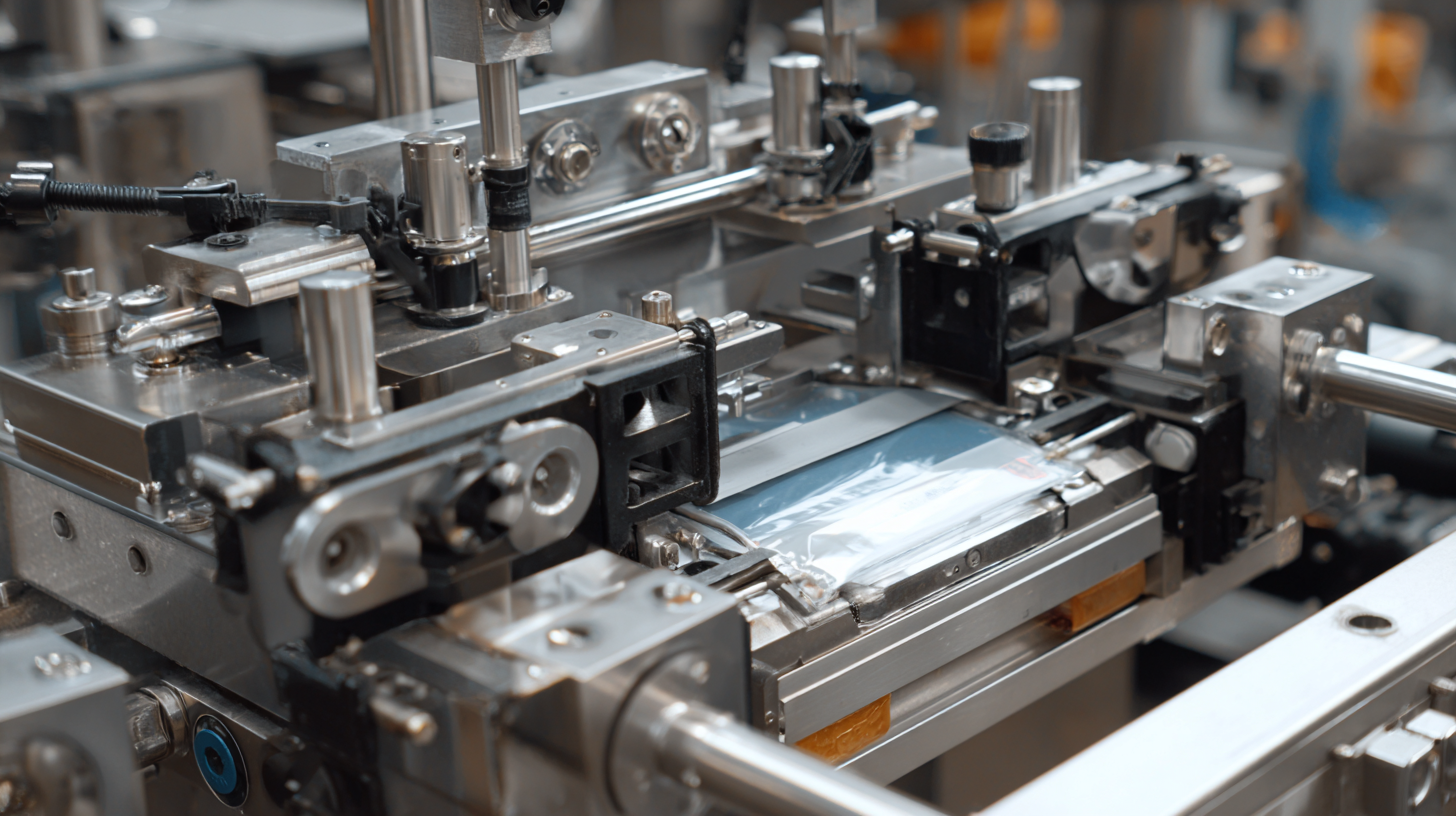

Efficiency Boost: The Role of Sealers in Streamlining Operations

In the fast-paced world of global procurement, operational efficiency is paramount. One of the unsung heroes of this efficiency is the bag sealer machine. By automating the sealing process, businesses can significantly reduce manual labor and time spent on packaging. This transition not only speeds up operations but also minimizes the risk of errors associated with manual sealing, ensuring that products are securely packaged and ready for shipment.

Tip: When selecting a bag sealer machine, consider investing in models that offer adjustable settings for different packaging materials. This versatility allows you to handle various products without compromising on sealing quality.

Moreover, a reliable bag sealer can enhance inventory management by making packaging uniform and easily stackable. This helps in optimizing storage space, resulting in streamlined logistics. With the right equipment, companies can also improve their overall product integrity, reducing the likelihood of damage during transport.

Tip: Regular maintenance of your bag sealer machine is crucial. Schedule routine checks to ensure that the sealing mechanism remains effective, which will prolong the machine's lifespan and maintain sealing quality.

Choosing the Right Bag Sealer: Factors for Global Procurement Success

When it comes to global procurement, selecting the right bag sealer machine can significantly impact operational efficiency and product quality. One of the primary factors to consider is the machine's sealing technology. Different products require various sealing methods, such as heat sealing, impulse sealing, or vacuum sealing. Evaluating the specific needs of your products can help you choose a sealer that maintains freshness and prevents contamination, ultimately reducing waste and enhancing customer satisfaction.

Another important aspect to factor in is the machine's adaptability to different packaging materials. Global procurement often involves a diverse range of products packaged in various materials. A versatile bag sealer can work with plastic, foil, or biodegradable bags, allowing companies to respond swiftly to market demands and sustainability trends. Moreover, ease of use and maintenance is crucial; selecting a user-friendly machine minimizes training time and reduces downtime, contributing to smoother operations across international borders.

5 Top Reasons Why the Best Bag Sealer Machine is Essential for Global Procurement

| Reason | Description | Impact on Global Procurement |

|---|---|---|

| Quality Control | Ensures packaging is airtight and secure, preventing product contamination. | Maintains product integrity during storage and transport. |

| Cost Efficiency | Reduces the risk of product spoilage and returns, thus lowering overall costs. | Enhances profitability in global markets. |

| Speed of Operation | Automates the sealing process, accelerating the packaging timeline. | Increases responsiveness to market demands. |

| Versatility | Compatible with various bag types and sizes, accommodating diverse products. | Facilitates a broader product range in global procurement. |

| Regulatory Compliance | Helps meet international packaging standards and regulations. | Reduces legal risks and enhances market access. |