About Us | Blog | FAQs | Tips/Troubleshoot | Contact Us | Machine Manuals | Demo Videos

Top 10 Tips for Choosing a Commercial Vacuum Sealer?

Choosing the right commercial vacuum sealer can significantly impact your business operations. Research indicates that the global vacuum sealer market is expected to grow at a CAGR of 5.1% from 2021 to 2028. This highlights the increasing demand for efficient food preservation and packaging solutions across various industries.

When selecting a commercial vacuum sealer, consider your specific needs. Do you handle bulk items or smaller products? The right model can streamline processes, reduce waste, and enhance product shelf life. However, not all sealers are created equal. Some may not handle high-volume tasks efficiently, leading to frustrations.

It's essential to weigh features such as seal strength, vacuum speed, and ease of use. Many users overlook the importance of after-sales support. A reliable supplier can make a significant difference in resolving issues. Ultimately, understanding your operational requirements and potential obstacles is key in choosing the right commercial vacuum sealer for your business.

Table of Contents

[Hide]

Understanding Vacuum Sealing and Its Benefits for Businesses

Vacuum sealing has transformed how businesses manage food storage and inventory. By removing air, vacuum sealing extends shelf life. According to industry reports, products sealed this way last 3-5 times longer than those stored conventionally. This means less waste and more significant savings for businesses.

Choosing the right vacuum sealer can feel overwhelming. Consider the volume of items you need to seal. If you're processing large quantities, an industrial model might be your best option. Remember, sealing smaller batches too often can lead to time and energy wastage. Ensure your choice can handle your specific needs without overkill.

Another crucial aspect is the seal quality. A weak seal can lead to spoilage. Regular testing and maintenance of the sealing mechanism are imperative. Investing in a model with adjustable sealing strength can help adapt to different materials. This flexibility can prevent issues that arise from using the wrong settings. A poorly chosen sealer not only affects food quality but can also lead to financial setbacks.

Top 10 Tips for Choosing a Commercial Vacuum Sealer

| Tip Number | Tip Description | Benefit |

|---|---|---|

| 1 | Determine the Volume of Sealing Needed | Helps to select a sealer that can handle the workload efficiently. |

| 2 | Consider the Size of the Products | Ensures that the vacuum sealer fits your products properly. |

| 3 | Look for High-Quality Sealing Mechanism | Ensures durability and effectiveness of the seals. |

| 4 | Evaluate the Ease of Use | Saves time and reduces training requirements for staff. |

| 5 | Check for Versatility | Allows for different types of sealing, enhancing productivity. |

| 6 | Inspect for Maintenance Requirements | Ensures long-term reliability and performance. |

| 7 | Review Customer Support Options | Provides assistance when needed for trouble-free operation. |

| 8 | Analyze the Cost of Ownership | Ensures that the investment aligns with budget and return expectations. |

| 9 | Request Demonstrations | Allows you to evaluate performance and functionality first-hand. |

| 10 | Read Reviews and Testimonials | Provides insight into the experiences of other users. |

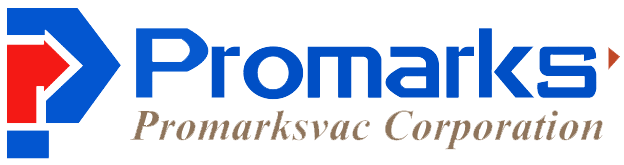

Key Features to Look for in a Commercial Vacuum Sealer

When selecting a commercial vacuum sealer, certain key features stand out. The sealing mechanism is crucial. Look for machines with reliable heat sealing. A good seal prevents air from entering the bags. This can significantly extend shelf life. Also, consider the pump strength. A stronger pump removes air more efficiently. This is vital for preserving food quality.

Another important feature is the size of the vacuum chamber. Larger chambers accommodate bigger bags and bulk items. Some businesses may need this for efficiency. Additionally, check for user-friendly controls. A complicated interface can lead to mistakes. Simple, clear buttons enhance usability, especially during busy hours.

Don’t overlook the durability of the materials. A cheaper model might save money now but can fail quickly. It’s worth investing in a quality machine. Note the warranty period and support options as well. Manufacturers with good support are valuable during emergencies. Always reflect on how often the machine will be used. Overbuying can lead to regret later.

Comparing Different Types of Vacuum Sealers for Commercial Use

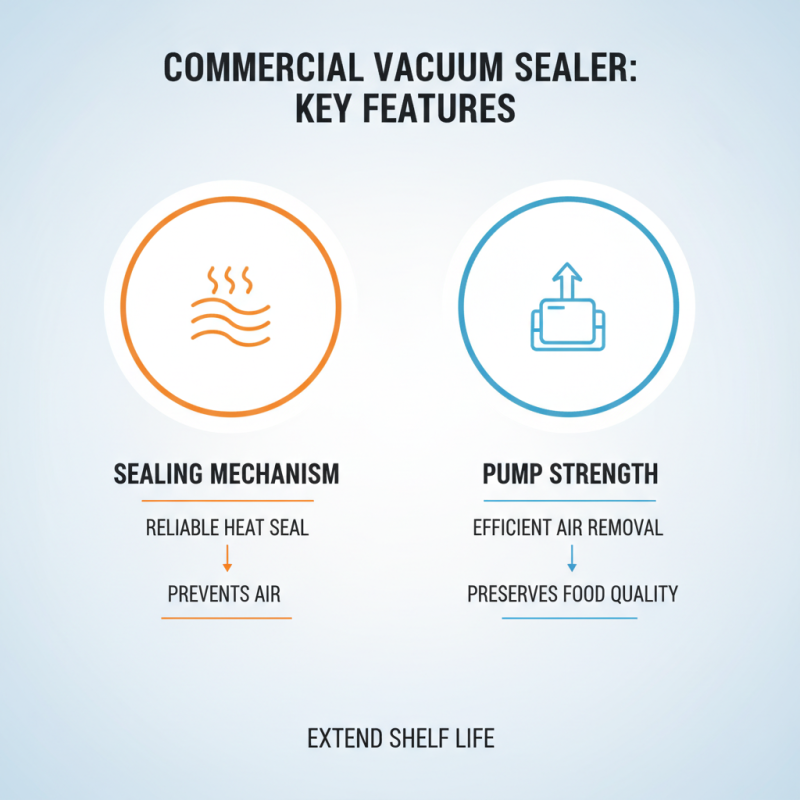

When comparing different types of vacuum sealers for commercial use, it’s essential to consider the specific needs of your business. Chamber vacuum sealers are highly effective for sealing liquids and wet foods, making them ideal for restaurants and food processors. These machines operate by removing air from a sealed chamber, which can lead to better preservation of moisture and flavor. However, they tend to be more expensive and require more space.

On the other hand, external vacuum sealers are generally more compact and budget-friendly. They are excellent for dry foods and simple sealing tasks, but they might struggle with liquids. It’s common for users to overlook the sealing process. If not done correctly, food can spoil faster than expected. Another point to consider is the longevity of the machine. Some options may seem cheaper upfront, but their durability may come into question after regular use. Being mindful of your workload and the types of food you deal with can prevent costly mistakes down the line.

Evaluating Cost vs. Quality in Vacuum Sealers

When evaluating cost versus quality in vacuum sealers, it's crucial to analyze the long-term benefits. Many businesses lean towards lower-priced options. However, studies suggest that cheaper models might not last as long. According to a market research report by ResearchAndMarkets, about 30% of economical sealers fail within the first year of use. This can lead to hidden costs, such as replacements and food spoilage.

Quality vacuum sealers often come with better materials and features. Users report a significant difference in sealing effectiveness. A survey from a leading food preservation organization indicates that high-quality sealers maintain food freshness for up to five times longer. This efficiency makes investing in a superior machine worthwhile, particularly for commercial applications.

Yet, it's vital to balance features with your operational needs. Some advanced features may be unnecessary for your specific use. An overly complex machine could lead to user errors. Thus, it’s important to reflect on what you truly need versus what is marketed. Understanding this can save money and ensure that the investment aligns with your quality standards and operational goals.

Maintenance and Support Considerations for Vacuum Sealers

When selecting a commercial vacuum sealer, maintenance and support are often overlooked. Regular maintenance is crucial for optimal performance. Studies show that vacuum sealers can lose over 30% of their efficiency without proper care. Cleaning the sealing element and drainage system weekly can proactively prevent breakdowns.

Technical support should also be a priority. Many businesses ignore the importance of fast, reliable support. A survey indicated that 70% of users who experience issues not addressed by timely support abandon the equipment. Understanding warranty agreements is vital. Some sealers come with limited warranties that can leave users vulnerable to additional expenses.

Investing in training for staff can reduce mishandling. One misstep can lead to costly operational downtime. Regular training sessions can help maintain the equipment and extend its lifespan. Industry experts recommend scheduling inspections every six months at a minimum. Regular maintenance and strong support can save money and ensure long-term reliability.

Top 10 Tips for Choosing a Commercial Vacuum Sealer

This chart illustrates the importance scores associated with various factors to consider when choosing a commercial vacuum sealer. The scores range from 1 to 10, reflecting their relative importance in decision-making.

Related Posts

-

Navigating Export and Import Certifications for the Best Commercial Vacuum Packing Machines in Global Markets

-

7 Essential Tips for Choosing the Right Commercial Vacuum Packing Machine

-

2025 Top Commercial Vacuum Packing Machine Buying Guide and Reviews

-

Ultimate Guide to Choosing the Best Industrial Vacuum Sealer Machine for Your Business

-

7 Reasons Why the Table Top Tray Sealing Machine is Essential for Your Business

-

Understanding the Benefits of Cryovac Machines for Food Preservation Techniques